Cleaning system

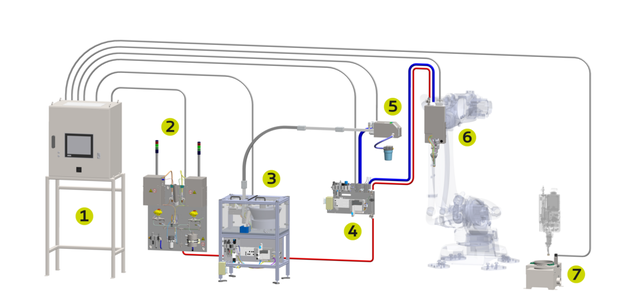

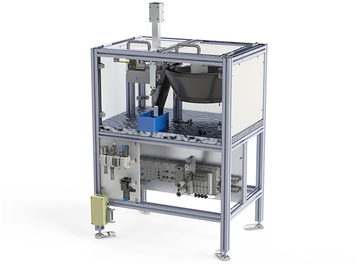

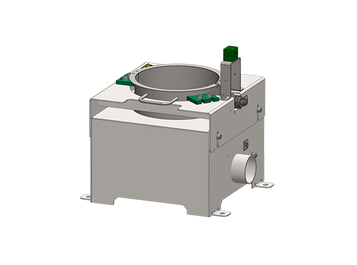

The complete ATMR-18 cleaning system

The patented ATMR cleaning system is used for both cleaning component surfaces and applying functional fluids before the application of adhesives and sealants. If grease, oil, or dust residues are present on the component, this can impair the adhesion of the material.

Unlike conventional cleaning methods with spray technology applied to the component, the advantage of our cleaning system lies in the precise dosing of the cleaning agent into a felt cube. The intelligent control technology can individually adjust the saturation level of the felt in each component section. This reduces emissions, saves cleaning materials, and limits the functional fluid to the adhesive bead path. For optimal cleaning results, the contact pressure of the applicator on the substrate can be adjusted as needed.

The intuitive operation of the system ensures smooth, fully automated production. Additionally, the smart design with a modular structure allows for easy integration into your system.

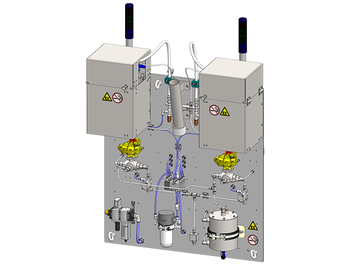

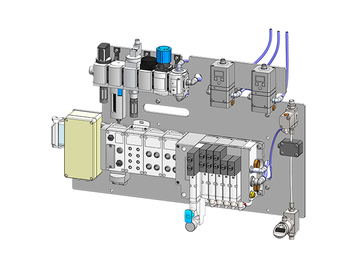

The pressure tank plate ensures uninterrupted operation of the cleaning system by utilizing two independently operating containers for functional fluids with automatic switching. The pneumatically controlled system operates at a standard pressure of 6 bar. Reliable process monitoring is ensured through integrated air bubble detection. Further information on media resistance is available upon request

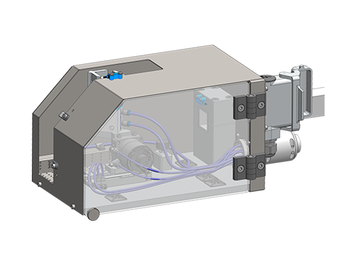

The spiral conveyor ensures the correct positioning of cleaning bodies through an electric vibration system. It stands out due to a wear-optimized design, as its moving parts have been reduced to a minimum.

The medium plate regulates the compressed air and material supply. Bubble and pressure sensors detect the flow of functional fluids to ensure smooth operation.

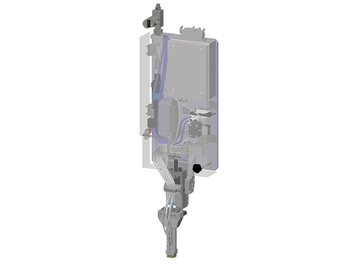

The transfer station ensures the precise transfer of the cleaning body from the spiral conveyor to the application head.

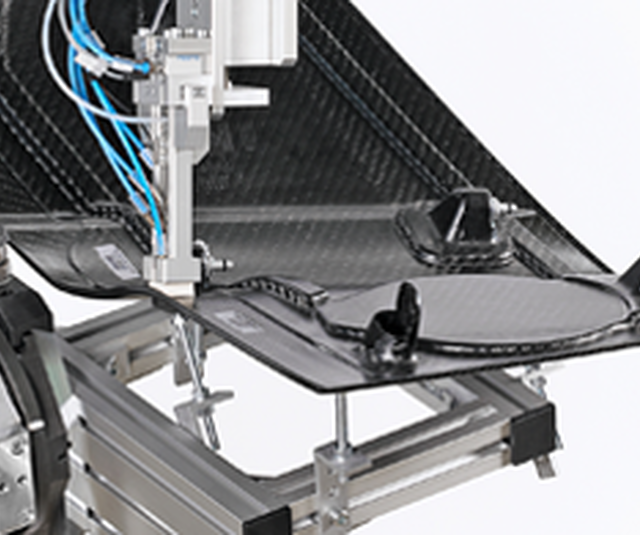

The application head enables precise application of functional fluids onto predefined substrate surfaces. Irregularities in the components are effectively compensated by pneumatic height adjustment and variable contact pressure. The amount of fluid applied can be regulated as needed and adjusted variably.

The used felt pieces are disposed of in the discharge container.

Our cleaning system is available in various configurations. For example, you can choose to mount the application head on either a robot or a stand. The felt pieces come in two different geometries (16 mm and 25 mm width). We are happy to advise you on your specific application!